Search This Site

Search With Google

Boat Moisture Meter

Moisture Meter Guide

The complete moisture meter website

A moisture meter proves itself to be a useful tool when testing the moisture content levels of boat materials. When assessing a boat, care, judgement and experience should all be employed and then the moisture meter used as the last tool to give the final assessment. It is possible to give a good assessment of a boats condition just by using visual observations, but with the advancements and uses of new materials within the boat building industry, more specialized equipment is required for testing and determining water and moisture problems.

The moisture meter can be reliably used to test and see if the hull core is wet. But this testing has to be done from inside the hull and not from the outside of the hull. When testing, the inner skin of the hull has to be dry and the boat not submerged recently as certain areas like the bilge can trap and hold water which will distort any moisture meter readings.

The moisture meter can be used anywhere on a boat from a foot or so above the water line to give reliable results. This is even so on decks just as long as all surfaces are dry and salt residue free.

Certain moisture meters can even work on non skid deck surfaces though the results can be somewhat distorted and the reliability of the readings reduced significantly.

The reliability of the moisture meter for testing boats is greatly enhanced when used by someone who is willing to experiment with it and knows what they are doing. For the person who is dependant upon the moisture meter and believes that all results are precise and correct, problems beckon. Using the moisture meter on boats requires a mix of science and skill and the results should never be taken as gospel.

Any readings you do obtain should never be reported as a percentage, but as a whole number and recorded as such with the make of moisture meter and the scale it uses.

Moisture Meter Guide 2010 Contact details:garnett65@hotmail.com

Tramex Skipper Plus moisture Meter

This moisture meter from Tramex is supplied with the necessary 9V battery, instruction manual and carrying pouch. It is a non intrusive meter, pocket sized, which has been designed for locating any moisture content in boat hulls and fittings. It can be used on wood and fiberglass and works just as well with fresh water as it does with salt water. This particular moisture meter has different ranges of sensitivity to allow for the testing in both fresh and salt water. The signal it sends out has a penetration of about an inch. The display is large and clear to read and you can even freeze the latest reading. Tramex skipper

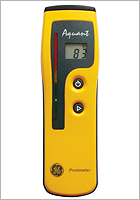

General Electric Aquant Moisture Measurement System

This protimeter aquant is very versatile. It can be used to test for moisture content levels in most building materials as well as being suitable for surveying boat hulls for early detection of damp spots which may lead to blistering. Features include a colour changing LED to highlight moisture condition, dual display, audible tone and zero out for temperature compensation. Aquant moisture reader

The moisture meter has been designed and manufactured to test for the moisture content levels in a variety of materials. Results will vary depending upon the materials which are being tested and the reliability of the moisture meter is brought in to question many times.

Now a moisture meter will function and give results in the way it is supposed to perform. However the problems are that there are many outside factors which can affect the result of a moisture meter.

Firstly, the way a person employs a moisture meter can result in many differing readings and secondly, the characteristics and environment in which the materials sit in, will produce results that are not unanimous.

So when using the moisture meter there are a few questions that need to be asked.

Does the density of the material that you are testing in any way affect the results of your meter? Plastic resins for example do differ in type and quality. Laminate density will differ greatly due to the fact that it is hand made.

Can a meter be used to test a boat hull that has just been hauled out of the water? Will any rainstorm affect the results of the meter?

Will the exterior finish of the boat affect the meter readings in any way?

Will the meter detect water content in a core?

Can a meter give accurate readings through a laminate on the inside of a boat hull? Or will these be false readings?

How does humidity and temperature affect a moisture meter reading?

Above are just a few questions that need to be asked when using a moisture meter. Any of the above issues can result in a different reading and affect your survey of the boat.

The main problem with working on boats is when the laminates are of unknown thickness and quality. Laminates have millions of voids and the outer layers can be extremely porous, resulting in large amounts of water be absorbed.

This is why blistering occurs. Structural laminates do not absorb water in the same quantities.

And where is the water situated that the moisture meter detects. It can be in the gel coat, the CSM layer, the structural laminates or the actual core. This is very hard to determine in the hull of a boat.

Now this is a huge issue as if water has got to the core of the hull, then it can have fatal results to a boat.

Testing Gel Coats

You need to know how gel coats perform. Which gel coats are more prone to water absorption and does the gel coat perform differently under and above the water line. Climate may also affect the performance of gel coats. Humidity levels do not really have much of an affect on gel coats, unlike that of wood.

When you test a boat deck after rainfall, after wiping the deck dry, the readings tend to be very low. This is because the gel coats are not subjected to water pressure as they are not below the water line. So they do not absorb much water. So any moisture meter reading of a deck is pretty reliable.

Salt will affect a moisture meter reading by up to 50% on any dry surface. So before testing , any salt residue needs to be wiped away.

To Care Is To Share

Fiberglass Boats And The Moisture Meter

Issues That Need Consideration When Using A Boat Moisture Meter

Testing A Boat

Recently Hauled From

The Water

If you pull a boat out of water and test it with the moisture meter within a short time of it leaving the water, the result will be high moisture levels.

The same test carried out after a couple of weeks later will give results significantly lower or even dry.

What this demonstrates is that freshly hauled boats hold residual moisture in the paint layers, gel coat and CSM layers.

On shore boats also tend to produce high readings. Testing a boat that is freshly hauled from the water can produce false readings and hence be unreliable.

Give the boat a couple of weeks before testing it.

The Depth That A Moisture Meter Will Read

Knowing how deep that a moisture meter will take a reading is of great importance. But that will depend upon the consistency and quality of the material that is being tested. Generally though, the denser the material to be tested, the deeper the meter will read. Your moisture meter will easily read through a half inch of vacuum bagged laminate, but will struggle to read through a hand lay up laminate. The meter will not read water through any type of dry core because the trapped air spaces will stop the meter’s signal.

False readings will be given when the meter is placed over a void or a laminate that has been starved of resin. To avoid false readings one can use the moisture meter in a scanning mode, rather than a spot testing mode. If you move your meter across the surface of an area and take readings they will be pretty accurate and give you a general surface result.

The problem with results from laminates is whether the results are applicable to moisture levels behind the laminate or in the laminate.

Techniques To Enhance The Reliability Of The Moisture Meter Reading

When testing the hull of a boat you should always use the moisture meter on the inside of the hull, as opposed to the outside of the hull. The reason for this is that the inner skin laminate is not submerged in water and hence is dry. If you obtain a wet reading on the inner skin, then this indicates that you have a wet core. The inner skin laminate will also be thinner than an outer skin laminate and not distort the reading of the meter as much.

False Readings

False readings with your meter can be the result of excessive CSM on the surface outer, fairing materials that are absorptive and paints which contain metals and oxides. So you do need to be a little wary of readings that are taken around keels, rudders and struts.

Any water that has been trapped in hull areas will affect any reading taken on a laminate. But water can not be detected through a dry core of foam or balsa.

False dry readings will result from a core that has rotted completely or broken down. If your boat is old then this is a significant issue as they have thick skins which do not deflect as much as newer boats. A rotted core will however leave hints such as brown water stains which leak out from the laminates.

Understanding Cored Structures

If you understand the nature of cored structures then you will know how and why they become saturated with water. You will also be in a position to know how to detect any water problems. For a structure that is curved, such as boats, the core materials are cut in to blocks to allow for conforming and bending in to curves. When these blocks are joined together, there will be gaps between these blocks. These are known as kerfs. Joining these blocks in a uniform contact is a huge problem if they are not vacuum packed and water can enter. All woods absorb water and any kerfs that are not completely filled with resin will allow the water migration to take place. Any water migration is also assisted by the continual forces of water against the boat hull and when the void areas of the core become completely filled with water, the core will just simply become a mush of fibres and slurry, and the skins will crack. Vacuum bagging is very successful at preventing water transmission because the vacuum forces resin in to the kerfs and blocks them.

Balsa can break down through hydraulic corrosion, rot or fungal degradation. Any starvation of oxygen will also corrode wood. By far the most frequent degrading of balsa hulls is by closed cell corrosion which is caused by lack of oxygen in the core which turns an water acidic. This acidic water will attack the structure of the balsa.

You can tell the type of degradation of balsa simply by it’s colour. Dark brown or black is the result of fungal issues, corrosion has little colour change and hydraulic corrosion has almost no colour change.

Foam cores have greatly improved over the years and are now stronger and reduce the transmission of water along their surfaces.

The moisture meter is an essential device to perform a good survey on a fiberglass boat. Fiberglass is a good material to use in boats as it has many good attributes. However it is not perfect and there are drawbacks.

When water enters a fiberglass structure, not much happens as long as the resin used has been properly cured and catalyzed and the core has no exposed core materials. If in the fiberglass any of the resin did not link to other components then the mix with water will result in producing a salt which is heavier than before the water entered. This salt will be trapped in the laminate and continue to grow and allow more water to enter. The water will attack the glue in the laminate and the laminate layers. Blistering will occur, delamination will take place and moisture levels will increase. The result being serious damage to your vessel.

A moisture meter can be used to determine how much moisture is present to give you a good idea as to the potential level of damage that can take place. Visual inspections will also assist in this. The moisture meter is very useful in determining how much water has been trapped within the laminate. If the moisture meter you use does detect the presence of moisture then more active procedures are required to determine the gravity of the problem. The moisture meter is your first step in detecting a moisture issue. Not the be all and end all and definitely not the rectifier of the problem.

Inside a fiberglass boat, small amounts of water will create problems if allowed to penetrate the layup. Once it wicks and spreads to other areas the problem can increase. One particular benefit of using a moisture meter on a fiberglass boat is that it can locate moisture penetration through hull fittings and deck hardware. This then gives you the opportunity to apply a marine grade sealant to the culprit and prevent any more water entry. One particular item to look for on decks is loose screws. If not tightened, massive rot problems can occur.

Fiberglass strands do not absorb water. Fiberglass is one of the very few materials that is unaffected by being submerged in water. Though it can be eroded by water flow of high pressure and speed.

A resin that has been properly cured and catalyzed will not absorbs amounts of water to affect it’s working properties.

One battle you are drawn in to as a boat owner is to take on mildew. And believe us it is a huge undertaking against a foe that is infinite in numbers, has all the time in the world and a breeding capacity that puts rabbits to shame.

Mildew or mold is a fungi which reproduces by spores. These spores can be dispersed in search of ideal growing conditions. If they do not find the conditions they want, they can lie dormant for many years. Some species for centuries!!

Mildew will eat almost anything and anywhere though they prefer the privacy of warm, damp and dark places. Somewhere like your boat for instance.

They breed like mad and eat anything and very quickly become visible masses if left unattended. They look bad, smell bad and can cause you health problems. As well as that they they will consume your boat over time. Encountering mold in your boat requires a popeye attitude, plenty of patience and an endless source of spinach!

There are mildew treatments and mildew resistant products on the market that you can buy. But do they really work? Nope, they just buy you time and a temporary solution. If you are one who sweeps dirt under the rug in home and think you have cleaned up, then these temporary measures will suffice for you. But you have been warned. You are only inviting chaos further down the line.

The climate that mildew prefers is a sub tropic climate. This is high humidity, warm temperature and still air. A sealed up boat in both summer and winter is a sitting duck for mildew to gatecrash and party all day, all month and all year long. Maybe you ban the sounds of Madonna in your home, but it wont be long before the mildew is moonwalking to "lucky star"

Do I detect a little a little contradiction here? Mildew needs warm, damp places to thrive, yet I say your boat can become a target in wintertime. How can this be so? A sealed up boat will have a little warmth in it, but the thing is with mildew is that it produces its own heat as well. Its digestive and life process produces heat and the larger the colony becomes, the more heat is produced.

Mildew will also attack closed spaces and lockers in your boat. And we all know that space is at a premium on a boat and the boat designers use every nook and cranny for storage space. Condensation is often caused in these nooks and crannys and that is when the mildew will march on defiantly. And lets not forget to mention that your boat floats on water. Condensation is caused when the cool hull meets the warm air in the cabin.

Household bleach is a sure and tested way of removing mildew. You can make this bleach even more effective by mixing in some tri sodium carbonate. You should never use household detergents combined with bleach. Always properly scrub the areas and surfaces and rinse thoroughly.

Our 2 Favourite Boat Moisture Meters

Mildew Wars

A website worth visiting in our opinion for all sorts of information on boat upkeep.

| Tramex Moisture Encounter Plus |

| Tramex Compact Wood Moisture Meter |

| Tramex Concrete Encounter Moisture Meter |

| Tramex Skipper Plus Moisture Meter |

| Tramex Roof And Wall Moisture Scanner |

| Sonin Digital Moisture Meter model 50218 |

| Sonin Digital Moisture Meter 270 model 50270 |

| Sonin Moisture Test Tool model 50210 |

| Sonin Moisture Test Meter Model 50211 |

| Oak |

| Douglas Fir |

| Beech Tree |

| Elm Tree |

| Hickory Tree |

| Maple Tree |

| Pine Tree |

| Prevent And Repair Gaps In Wooden Floorboards |

| How To Fix A Squeaky Hardwood Floor |

| How To Repair A Hardwood Floor That Has Buckled |

| Which Is The Best Firewood? |

| Concrete |

| Concrete Moisture |

| Screed Moisture Meter |

| SDS Drill |

| Belle Cement Mixer |

| SDS Drill Advice |

| Which SDS Drill |

| SDS Drill Accessories |

| Drilling Into Concrete |

| Kennedy Tool Box |

| Moisture - Basic Facts |

| Types Of Damp |

| Wet Rot |

| Dry Rot |

| Mold |

| Water Leak Detection |

| Stucco Moisture |

| Water Damage |

| Moisture And Rust |

| Moisture Damage To A Chimney |

| Wallpaper Stripper |

| Plaster Mixer |

| Why Worry About Moisture Problems |

| Does Your Home Have A Moisture Problem? |

| How To Solve Moisture Problems |

| How To Use Anti Mold Paint |

| Rising Damp |

| Condensation |

| Salt Damp |

| How To Avoid Bathroom Condensation |

| How To Remove Black Mold |

| How To Prevent Bathroom Mold |

| Soldering Kit |

| Soldering Kit Contents |

| Soldering Kit Advice |

| Bonsai Tree Classification |

| Growing Bonsai From Seed |

| Bonsai Tree Care |

| Bonsai Tree Training |

| Bonsai Tools |

| Displaying Bonsai |

| Bonsai Calendar |

| Bonsai Plants |

| The Thirsty Light Curve Moisture Meter |

| The Thirsty Light Ladybird Moisture Meter |

| The Thirsty Light Bumble Bee Moisture Meter |

| The Thirsty Light Butterfly Moisture Meter |

| Hanna Instruments |

| Agratronix Portable Coffee Moisture Tester |

| Lawn Aerator |

| Lawn Roller |

| Lawn Rake |

| Lawn Sand |

| Chainshot |

| Chainsaw Gloves |

| Chainsaw Trousers |

| Chainsaw Boots |

| Mac 4 - 20 XT Chainsaw |

| Mac 738 Chainsaw |

| Mac 842 Chainsaw |

| Mac 20X Power Chainsaw |

| Einhell BG-PC 3735 Chainsaw |

| Einhell BG-PC 4040 Chainsaw |

| Einhell BG-PC 5045 Chainsaw |

| Poulan P3314 Chainsaw |

| Poulan P4018 Chainsaw |

| Poulan Pro PP3816AV Chainsaw |

| Poulan Pro PP4218AVX Chainsaw |

| Poulan Pro PP4620AVX Chainsaw |

| Efco MT 4100 SP Chainsaw |

| Efco MT 3500 Chainsaw |

| Efco 132 S Chainsaw |

| Efco 147 Chainsaw |

| Efco 152 Chainsaw |

| Efco MT 7200 Chainsaw |

| Efco MT 8200 Chainsaw |

| Efco MT 3750 Chainsaw |

| Methods Of Obtaining Soil Moisture Levels |

| Hygrometer |

| Psychrometer |

| Rain Gauge |

| Wave Ventilation System |

| Humidity |

| Hygrometer For Keeping Reptiles |

| Humidor |

| Weather Stations |

| Musical Instrument Storage |