Search This Site

Search With Google

Wood Moisture Meter

Using The Wood Moisture Meter

Moisture Meter Guide

The complete moisture meter website

For testing the moisture content levels of wood and timber, the wood moisture meter is an essential instrument to use. Being versatile it can test moisture levels in furniture wood, firewood and flooring timbers. Pinless and pin type meters are both options available with the pinless type very often preferred due to it´s non destructive way of working. For the woodworker, moisture can be a severe issue as in excess or lack of, the result can be severe damage to any finished product. Ask a cabinet maker which his most important tool is and you will not be criticized for assuming it is a chisel. However the wood moisture meter is on par in importance with the chisel. No specialised wood worker will be without one.

Any flooring contractor will also swear by the moisture meter. They are not just used to measure moisture levels in floorboards, but also to detect any possible moisture migration to the surface which will have devasting affects on any finished floor. As well as this they can also be used to test the surface and mid section concrete that a floor will be layed upon. The laying of a floor can be a huge job with high financial investment. This is why it is so important to get the job done correctly without any moisture content hiccups.

Understanding The Wood Moisture Meter And Testing Wood

The moisture meter is a very common instrument used by many professionals in their working capacity. It is particularly utilized in the construction industry, home inspection industry and the wood industry. The meter has been designed and manufactured to enable any user to be able to accurately test for moisture content in an array of materials. They are simple to use and only the basic knowledge of how they work is required. But one must be a little wary of using one as the specifics vary on each model and a variety of factors can influence and affect a moisture level test. Using the instrument incorrectly is also very easy to do.

In construction and inspection industries moisture can prove to be of grave concern and workers in these spheres really do need to know how to utilize a moisture meter properly and analyze results. There is a wide range of moisture meters available, each specifically designed to test different materials as moisture itself will affect each different material in a unique way.

When it comes to testing wood, the pin type moisture meter is typically the choice. They perform an invasive method, employing pins which can be of different lengths depending on the meter and of course the user’s requirements. The pins can be anything from ¾ of an inch up to 3 inches in length are are inserted in to the wood that needs testing. The resulting reading is converted by the moisture meter in to a moisture content result with a higher reading meaning a higher moisture content in the wood.

The pin moisture meter will have either insulated or un-

Moisture in wood can also be measured by pin less moisture meters. These meters do not penetrate the wood and instead the meter is placed against the wood and a sensor will detect moisture and give a reading. These non invasive meters have the ability to take a few readings of wood in a short time.

When using a moisture meter to test wood there are several factors that need to be taken in to consideration. The particular moisture meter choice is the first. Specifics of each meter are important as are the depth capacities of the meters. You need to know the depth capacity of your instrument as each meter can be calibrated to different depth levels.

Surface moisture on any given material can result in a false reading so it is imperative that the pins on a pin meter are kept in tip top condition. If the pins become a little worn or appear not to function so well, replacement pins can be purchased to replace the faulty pins. Remember that a pin moisture meter will always leave holes in the wood, so test areas that will not be visible to the naked eye on a finished product.

The majority of moisture meters are designed for use in a parallel fashion to the wood grain. Some however are not and if you have one which is not you need to know that. There are different testing techniques in this case and again one needs to refer to the operating manual for guidance.

What is wood?

Found in the stems and roots of trees, wood is a hard and fibrous structural tissue. For thousands of years is has been used as both a fuel and construction material.

Basically it is an organic natural composed of cellulose fibres which are embedded within a matrix of lignin and can withstand and resist compression.

There are many physical properties to wood and many uses for it. What is wood?

Dry Wood

When working with wood you want it dry to achieve the best results. Working with wet wood will cause you all sorts of problems further down the line in quality aspects. Before working with wood it is highly advisable that you test it for moisture content with the moisture meter, and only work with it if it is dry enough.

Wood is a biological material and when it is in the tree it will contain large quantities of water for the tree’s sustenance. Now when wood dries and it’s moisture content becomes in equilibrium with it’s environment, this wood will actually go through a property and characteristic change.

Wood shrinks when it dries. When trees are cut lumber yards will use a lumber dryer to dry the wood. This pretty much eliminates wood shrinkage and swelling to the end user providing the wood is stored correctly.

Dry wood remains in good condition and there is little likelihood of new cracks and splits developing.

Dry wood does not decay. Mould and mildew will stay away and the wood will not stain. The reasons for this is that if the moisture content is low in the wood then there is simply not enough moisture present for fungi to thrive.

Working with dry wood is easier than working with wet wood. It is lighter and in certain species of wood can be lighter by up to 50%.

Dry wood is stronger, about twice as strong actually, as wet wood.

Dry wood can be fastened, glued and machined better than wet wood.

Dry wood is easier to treat with any fire retardant compared to wet wood.

So when you look at the advantages dry wood has over wet wood, it is understandable why it is so essential to work with dry wood. This is why you need a moisture meter and must test wood before working with it.

How Dry Should Wood Be ?

There are 5 basic conventional methods of drying wood in process today. These are air drying, forced air drying, low temperature drying, kiln drying and high temperature drying. Each particular method has it’s own characteristics which affect the performance and cost for each particular species of wood.

Wood needs to be dried so that the moisture content is within 2% of it’s in use moisture content. For such items as furniture to be used in the home the in use moisture content is approximately 6 to 8%. If the climate is a drier climate then adjustments have to be made to this equation.

Wood for outdoor purposes tends to be dried with a higher moisture content. Usually it has a moisture content of 12 to 16%. For wood that needs to be bent the moisture content will be about 25% for severe bending and about 18% for light bending. Softwoods are dried to about 19%.

What is worth remembering when drying wood or testing wood with the moisture meter is that temperature does not have any real effect. It is the humidity and wood moisture content relationship that is the critical factor.

Wood And Water A Bad Mix

There is no doubt that a wooden floor will grace any home or office and enhance it. They also prove to be extremely durable and easy to keep clean. However if the wooden floor is not installed properly, a wooden floor can prove to be a nightmare.

A growing tree holds a lot of water and moisture. The tree sap that runs through the tree’s cells carries water from the roots to the leaves and branches. Tree cells are like drinking straws and suck up water. Now when a tree is cut down it will lose moisture because it is no longer attached to the root system. However the cell structure still allows wood to absorb moisture which comes from air humidity. That is the nature of wood. Properly dried wood will improve the situation greatly, but the wood will still absorb moisture if there is any around. And as stated earlier, wood will change when it becomes moist. Acclimatizing helps and even treated wood deals with a lot of moisture. However there is no way of eliminating the absorption qualities of wood. Working with wood requires having the wood in the best possible condition for it’s respective environment. An important part of ensuring that wood is in tip top condition is the moisture test. The moisture meter will not make the wood be in perfect condition but help you to make an important decision in it’s suitability.

Moisture Meter Guide 2010 Contact details:garnett65@hotmail.com

Wooden Floors

These days the species of wood that can be used for a wooden floor has increased significantly. There are soft woods and hardwoods to choose from till your heart’s content. The colourings and designs offer a vast range of alternatives, function ability and of course cost. For the floor layer each specific species of wood offers a different challenge. But each species of wood has one common feature. Moisture absorption.

So when working with exotic woods one needs to know the individual characteristics of each species. They absorb moisture at different rates and quantities and also act differently to moisture. Take cork for example. Perfect for offering a soft floor that absorbs sound and impact. But that is not all it absorbs. Cork is notorious for absorbing moisture. It is a moisture sponge. So laying cork in the kitchen or bathroom can prove to be an expensive mistake. Testing cork with a moisture meter also proves to be inaccurate.

Other woods like Wenge, bamboos and Brazilian cherry make excellent hardwood floors. They are strong and can resist most dents. Oak is often considered to be an excellent hardwood for flooring but the above alternatives are so much more superior. So it goes to show, when working with wood, take the time to learn about each species and their characteristics towards moisture. The knowledge you gain will prove to be invaluable in the long run.

Firewood Moisture Meter

If you have a log fire or log burning stove the firewood moisture meter is arguably the most important tool you have to help you get the most out of your fire or stove. The trick to having a great log burning fire or stove is to feed them with well seasoned wood. In order to ensure that you use well seasoned wood you need to test the wood for moisture content with your moisture meter. Obviously there are many firewood suppliers out there for you to purchase your logs from. And each will say that their product is well seasoned. In many cases this will be so, but there is no harm in having your own moisture meter and making your own tests as the quality of the fire logs. A test is quick to do and the moisture meter will give you the results almost immediately.

If you use logs on your fire or in the stove which are not well seasoned you will experience a lack of heat and if your stove has a window you will notice that it is getting tarred up. Bad logs will also result in tar forming in your chimney. Basically with bad unseasoned logs you are wearing out your stove and chimney as well as producing high levels of particulates which can have unwanted effects upon your health.

If you are buying firewood you need to check with the seller as to which type of firewood it is. It could be well seasoned or freshly processed. When the delivery arrives check a couple of logs with your moisture meter before it is unloaded. You can check the logs by splitting them in half and applying the moisture meter. If the firewood is good you will get a reading of about 20% or less. If the reading from the moisture meter is higher than this then the logs are obviously wetter and not seasoned. Whether you accept the delivery is entirely up to you. But if you have ordered well seasoned wood and it is not then you need to negotiate a lower price or refuse delivery.

When it comes to storing and seasoning your firewood logs the moisture meter will prove itself to be an invaluable instrument. Storing and stacking firewood should be done on a south facing wall. Over a period of about 4 months the moisture content will drop from around 50% to 18% if you have chopped the wood yourself. You can also store it in wooden stilliges. Storing firewood is simple enough but knowing when to burn the logs is another matter. Testing the moisture levels unfortunately can not be done by “touch”. The firewood moisture meter is the only way to go. They are however very easy to use and fit in the hand snugly enough. The only way to test firewood is to split it and test on the inside. Firewood is always drier on the outside. So split the log and push the meter pins in to the freshly split faces. Ideally you want to test in the middle of the log and press the power button of the meter. You can freeze the reading if you so desire and when you are finished just turn the moisture meter off.

Which Is The Best Firewood?

It is a good and important question to ask. There are differences between how different types of firewood burn. Dense hardwoods and softwoods have different structures and hence will burn differently. Also certain firewood will produce more ash and creosote build up than other woods.

The main factor that determines how a wood will burn is the density of the wood. Dense hardwoods will burn a lot slower and give off more energy than softwoods because there is more wood fibre per density in them. Best firewood >

Wood Moisture Meter Basics

Newly cut logs will have a moisture content of about 80%. When wood dries it can shrink, split, twist and change shape. This is why it is imperative that wood is dried before use. After drying wood must be tested for it’s moisture content before application. If wood is not dried to the correct levels, working with it can result in dire consequences. This is why the moisture meter for wood has been invented.

The amount of change in wood varies from species to species when it dries. Some woods such as teak and mahogany are less prone to distortion as they dry whilst such woods as pine and oak can change dramatically.

A moisture meter is used to assist in any woodworking applications and will give an approximate reading of moisture content in wood. Though not 100% accurate the readings from the moisture meter will assist the woodworker in deciding whether a particular piece of wood is ready to be worked with.

Laying A Wood Floor

Laying a wood floor can be a huge job so it needs to be done correctly. It is not as simple as many of the DIY home stores make out. It is not just a matter of purchasing floor boards, laying them out and then slotting them together, to give you an instant splendid floor. Laying floor boards is easy enough to do, but to ensure having a quality floor that will remain trouble free, there is a little more work and preparation required.

Moisture is a huge enemy of wood and can cause all sorts of problems. And this can be particularly evident with wooden flooring. When laying floorboards there are other layers that need to be considered because they can cause moisture issues.

Now if you are laying a wood floor over concrete the moisture content in the concrete can cause serious issues with the finished floor. For example if it is a concrete slab and has not dried out properly, the moisture will wick it’s way to the surface of the concrete and affect any adhesive on the floorboard or even cause wood warping and cupping. Treating moisture problems underneath a wooden floor can prove to be a long , expensive and laborious job. Any concrete slab that has cracked or has moist patches will also provide moisture problems that can affect a wood floor. So as you can see , concrete moisture can be a real serious issue when it comes to laying floorboards over it. So one must test concrete with a moisture meter to ascertain if there is any moisture content problems before even considering laying a floor.

When laying a wood floor you will have the base, could be concrete, then the wood sub floor. Now the wrong moisture content in a wood sub floor will eventually lead to moisture related issues with the finished floor. So the wood sub floor must be tested for moisture content with a moisture meter. Both the pin and pin less meter are suitable to carry this test out with. The pin moisture meter has more advantages in this case as you can actually test different depths. When testing the sub floor the results you want are about 3 to 4% of the flooring that is to be installed.When you have tested the concrete and sub floor moisture levels and are happy that they are at the correct levels. Do not yet lay the boards. You also need to check the boards. Take a couple of bundles and open them up and test them with an accurate moisture meter. You want all the boards to have a consistent moisture content and also to be compatible with the sub floor. Either the pin or pin less moisture meter is suitable for this task. If all moisture levels are satisfactory then you can go ahead and lay your new floor with complete confidence.

One issue we have not touched on here is humidity. This can affect a wooden floor greatly and is not tested using your wood moisture meter. A good way to overcome this issue is to allow your floor boards to sit and acclimatize to the particular surrounding factors such as humidity.

Testing A Wood Floor For Moisture

If you have a wooden floor and notice problems of warping and such, then you may have a moisture issue that needs to be dealt with. When laying a wooden floor, moisture tests should be carried out throughout each process. After installation you still need to check moisture levels on a regular basis. Doing this can prevent any long term damage and problems with your flooring. Problems can include shrinkage and swelling of your floor boards.Any increase in moisture levels will result in swelling whereas decreases in moisture levels will result in shrinkage. Either symptom will have adverse effects on your flooring.

If you have a fully installed floor and notice swelling or shrinkage, then is perfectly reasonable to assume that you have a moisture problem. The way to test for this is to lift the floor boards and start working with your moisture meter.

Moisture Testing Tips

Check the sub floor for moisture. An electronic moisture meter is good for this. You could also use a calcium chloride test to the same effect.

If the sub floor is wooden use a probe moisture meter. This allows you to test at depths.

Repeat the testing several times over as much of the area as you can. Write down your readings and with mathematics you should be able to locate the problem area.

If you do have a moisture problem you want to test on a daily basis for a short period of time. Any professional flooring contractor will be able to advise you on this process. Measures then have to be taken if you have moisture issues.

Wood Moisture Meter For Boats

Another application for the wood moisture meter is that with boats. Many boat owners or marine surveyors will own and use a moisture meter. In fact it does not matter if the boat is made out of wood or fibreglass, the wood moisture meter will function equally as well. Both the pin and pin less moisture meters are suitable and preference is down to yourself.

Choosing a moisture meter to use on your boat is very similar to selecting a moisture meter which was covered on a previous page within this site. Basically select the meter best for the job and that suits you and your budget. Ascertain the correct materials your boat is constructed from and purchase accordingly. Always follow the correct operating procedures that are supplied in the user manual and you will have yourself an excellent instrument that will work effortlessly and help you with an moisture readings your require.

Buying A Wood Moisture Meter

Moisture Meter Brands On This Site

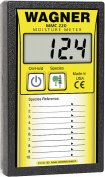

Wagner

General Tools MM1E Pin LED Moisture Meter

General Tools MMD5NP Pinless LCD

General Tools MMD7003 Precision

General Tools MMD8P Multi Species

|

|

60 |

65 |

70 |

75 |

|

70 |

11 |

12 |

13.1 |

14.4 |

|

80 |

10.8 |

11.7 |

12.9 |

14.2 |

When EMC has been reached in wood in a situation where the relative humidity and temperature do not change, the wood is stable and ideal conditions have been reached. EMC of wood >

Relative Humidity

Boat Moisture Meter

A moisture meter proves itself to be a useful tool when testing the moisture content levels of boat materials. When assessing a boat, care, judgement and experience should all be employed and then the moisture meter used as the last tool to give the final assessment. It is possible to give a good

Caravan Moisture Meter

Floorboard Advice

Wooden floorboards must be acclimatized >

Prevent and repair gaps in wooden floorboards >

Damp can invade your caravan through damaged seals, poor plumbing and inadequate cleaning. Without treatment you will find yourself having real problems as both mold and mildew can flourish in a damp caravan.

For a highly informative and an excellent read, this blog is well worth any time you invest in it.

Equilibrium Moisture Content Of Wood

Wood is always sensitive to moisture. It will absorb and release moisture until it is in an equilibrium state with the surrounding atmosphere it is in.

Examples Of The Wood Moisture Meter

Wagner MMC220 Moisture Meter

This particular moisture meter from Wagner is an ideal and lightweight non damaging meter for testing moisture in wood. Because it is lightweight and portable it finds a home with many woodworkers and industry professionals. It can be used to scan quickly and provide results quickly and accurately.

Pinless

Intellisense

Digital display

Moisture range 5 -

Precision 0.1%

Working depth ¾ inch

Press and hold

Delmhorst 32000 Moisture Meter

Here we have an example of the moisture meter that is designed for testing wood.. It is a pin version and is packed with many features that make it a popular choice among woodworkers and furniture makers. When you buy one of these new it comes with extra contact pins and a very nice carry case.

Micrcontroller circuit

Can be used on 48 species

Can be used with an external electrode

Moisture range 6 -

Averages up to 100 readings

Stihl Wood Moisture Meter Digital Damp Meter Tester Detector Wood Timber Moisture

Whilst looking around and checking out models of the firewood moisture meter we came across this model from Stihl. Stihl is one of the largest chainsaw producing companies in the world, so it is fair to say that they know wood and timber and that this moisture meter will be more than suitable for testing any cut wood.

This Stihl moisture meter can be used to measure the moisture content in cut wood, paper and cardboard. We have also been told that it works perfectly well on harder materials such as concrete as well. It is a nice size and the display reading is large and clear. Built in to this moisture meter is a thermometer as well which can measure the temperature of a surrounding area. For more on this moisture meter check out the official website at Stihl Moisture Meter

Oak Tree

There are about 600 species of the oak tree native to the Northern Hemisphere. They include decidious and evergreen Oak Tree >

Beech

The beech tree is a decidious tree and belongs to the fagaceae family. It is a native tree to Europe beech tree>

| Tramex Moisture Encounter Plus |

| Tramex Compact Wood Moisture Meter |

| Tramex Concrete Encounter Moisture Meter |

| Tramex Skipper Plus Moisture Meter |

| Tramex Roof And Wall Moisture Scanner |

| Sonin Digital Moisture Meter model 50218 |

| Sonin Digital Moisture Meter 270 model 50270 |

| Sonin Moisture Test Tool model 50210 |

| Sonin Moisture Test Meter Model 50211 |

| Oak |

| Douglas Fir |

| Beech Tree |

| Elm Tree |

| Hickory Tree |

| Maple Tree |

| Pine Tree |

| Prevent And Repair Gaps In Wooden Floorboards |

| How To Fix A Squeaky Hardwood Floor |

| How To Repair A Hardwood Floor That Has Buckled |

| Which Is The Best Firewood? |

| Concrete |

| Concrete Moisture |

| Screed Moisture Meter |

| SDS Drill |

| Belle Cement Mixer |

| SDS Drill Advice |

| Which SDS Drill |

| SDS Drill Accessories |

| Drilling Into Concrete |

| Kennedy Tool Box |

| Moisture - Basic Facts |

| Types Of Damp |

| Wet Rot |

| Dry Rot |

| Mold |

| Water Leak Detection |

| Stucco Moisture |

| Water Damage |

| Moisture And Rust |

| Moisture Damage To A Chimney |

| Wallpaper Stripper |

| Plaster Mixer |

| Why Worry About Moisture Problems |

| Does Your Home Have A Moisture Problem? |

| How To Solve Moisture Problems |

| How To Use Anti Mold Paint |

| Rising Damp |

| Condensation |

| Salt Damp |

| How To Avoid Bathroom Condensation |

| How To Remove Black Mold |

| How To Prevent Bathroom Mold |

| Soldering Kit |

| Soldering Kit Contents |

| Soldering Kit Advice |

| Bonsai Tree Classification |

| Growing Bonsai From Seed |

| Bonsai Tree Care |

| Bonsai Tree Training |

| Bonsai Tools |

| Displaying Bonsai |

| Bonsai Calendar |

| Bonsai Plants |

| The Thirsty Light Curve Moisture Meter |

| The Thirsty Light Ladybird Moisture Meter |

| The Thirsty Light Bumble Bee Moisture Meter |

| The Thirsty Light Butterfly Moisture Meter |

| Hanna Instruments |

| Agratronix Portable Coffee Moisture Tester |

| Lawn Aerator |

| Lawn Roller |

| Lawn Rake |

| Lawn Sand |

| Chainshot |

| Chainsaw Gloves |

| Chainsaw Trousers |

| Chainsaw Boots |

| Mac 4 - 20 XT Chainsaw |

| Mac 738 Chainsaw |

| Mac 842 Chainsaw |

| Mac 20X Power Chainsaw |

| Einhell BG-PC 3735 Chainsaw |

| Einhell BG-PC 4040 Chainsaw |

| Einhell BG-PC 5045 Chainsaw |

| Poulan P3314 Chainsaw |

| Poulan P4018 Chainsaw |

| Poulan Pro PP3816AV Chainsaw |

| Poulan Pro PP4218AVX Chainsaw |

| Poulan Pro PP4620AVX Chainsaw |

| Efco MT 4100 SP Chainsaw |

| Efco MT 3500 Chainsaw |

| Efco 132 S Chainsaw |

| Efco 147 Chainsaw |

| Efco 152 Chainsaw |

| Efco MT 7200 Chainsaw |

| Efco MT 8200 Chainsaw |

| Efco MT 3750 Chainsaw |

| Methods Of Obtaining Soil Moisture Levels |

| Hygrometer |

| Psychrometer |

| Rain Gauge |

| Wave Ventilation System |

| Humidity |

| Hygrometer For Keeping Reptiles |

| Humidor |

| Weather Stations |

| Musical Instrument Storage |